Due to the early dismantling technology used in the aluminum mold, only the support rod is left, and the dismantling time of the support rod is determined based on the strength of the test block.

In general, after 12 hours of concrete pouring, the side formwork of the wall column can be removed. The diagonal support should be removed first, and then the wall bolts should be removed. To remove the through wall bolt, a wrench is used to loosen the nut, remove the gasket, remove the back ridge, lightly tap one end of the bolt until the bolt exits the concrete, and then remove the pin connecting the template. Use a crowbar to pry the template to separate it from the wall. The dismantled templates and accessories should be cleaned in a timely manner, and transported to the same position on the previous layer and stacked flat.

In general, the top formwork can be removed after 36-48 hours. The removal of the top formwork starts from the position of the beam and plate support rods, and the pins and connecting parts of the beam and plate support rods are removed. Following the removal of the pins of the beams and slabs, the formwork can be removed. Use a pry bar to pry it off from the junction between the formwork and the concrete, and ensure that the supporting rods remain in their original state and are not loose during removal. The dismantled templates and accessories should be cleaned in a timely manner, and transported to the same position on the previous layer and stacked flat.

Determine the demolding time of the support rod based on the retained demolding test blocks. In general, the bottom support of the plate is removed after 10 days, the bottom support of the beam is removed after 14 days, and the cantilever support is removed after 28 days. When removing each support, use one hand to grasp the support rod, and the other hand to loosen the direction with a hammer. Hammer the adjustable support point to remove the support rod.

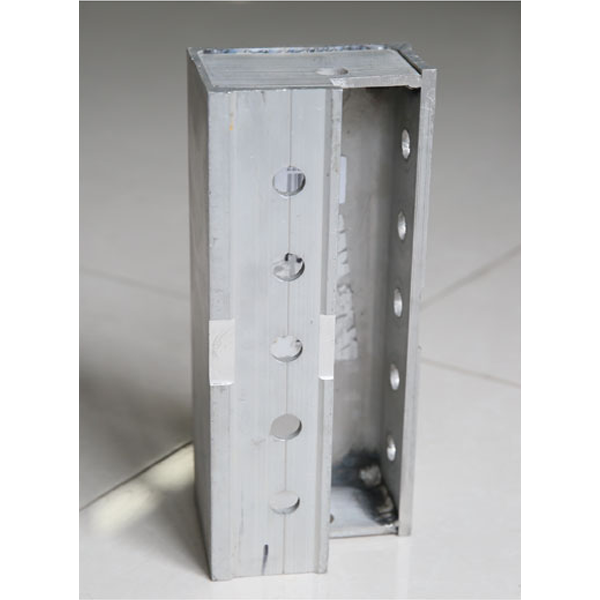

The removal of the aluminum template for the inner wall uses the bottom of the aluminum template as the pivot to leave the concrete. Use a pry bar to separate the aluminum template from the concrete on the side of the wall, and then use a dedicated pull rod for aluminum template removal to remove it. During the demolition process, surface peeling should be avoided, and special attention should be paid to avoiding damage to the corners and ends of the wall during formwork removal.

After removing the connection between the aluminum template and the outer guide wall panel, the external wall aluminum template can be directly pulled off the concrete from the top using a tower crane, cleaned on site, and lifted directly to the same position on the next floor.

The removal of the floor panel bottom aluminum template and beam bottom aluminum template starts from the floor keel. The pins and connecting rods between the keel and the support head should be removed first, and then the pins and wedges between the keel and adjacent floor templates should be removed, and then the keel can be removed. The dismantled aluminum template is transported to the upper layer through reserved delivery holes or floor voids, and scattered accessories are transported through stairs.

Antai Aluminum Template has a professional service team to always solve the problems encountered by customers during the construction process and avoid problems during construction.